The Dirt About Dredging

Introduction

This is a post about dredging. It's an assignment my dad and I took on together to “create a post about dredging and make it as interesting as we can.”

Wait. Don’t leave! Remember our anchoring post? You might find this one pretty cool, too.

In all our blog posts, we try to relate them to being on our Nordhavn. Here, you’ll see how important dredging has been to our 3-1/2 year live-aboard experience.

Ancient History Of Dredging

Ever since civilization began, dredging was critical for trade, because all vessels, no matter how small, need water depth to navigate without running aground. The earliest way to improve depth was to remove sediment by hand.

There is evidence of this on the Tigress and Euphrates rivers in West Asia, and the Nile river in Africa, dating back to around 3500 BC, the approximate beginning of the Bronze Age!

As time marched on, dredging methods improved. There is extensive evidence of harbor dredging between 300 BC and 100 AD in the eastern Mediterranean Sea at Marseilles, France, and Naples, Italy.

At the ancient harbor in Marseilles, archeologists have found three ancient dredging boats on the bottom, and in Naples, scouring on the faces of rocks shows clear evidence of some form of mechanical dredging. After the fall of the Roman Empire, many of the ancient harbors built by Roman slaves fell into disrepair and eventually were buried by the sea.

Wreck of ancient Roman dredging ship. Marseilles, France. From 1st or 2nd centuries AD. Photo source: ResearchGate.net

In the 15th century, the Dutch invented a machine called called the "Zeeuwse Krabbelaar," which translates in English to the Zeeland Scribbler, a machine that scratched up the mud on the bottom of the river, so the current to could wash it away.

The Zeeuwse Krabbelaar. Photo source: Lowtechmagazine.com

Around 1575, another machine was developed called a “mud mill.” It used a rotating chain and wooden boards to dig up the mud. Though the Dutch machine was powered by men, and the mud mill was powered by men and horses, the invention of the steam engine eventually automated these machines. In fact, the steam engine revolutionized dredging, allowing bigger, more powerful machines such as bucket dredgers, to remove far more material than before.

Mud mill dredger. Photo source: Startdredging.com

It might amaze you to know that Leonardo da Vinci designed a dredging machine during the Renaissance. (The Renaissance, between the 14th and 17th centuries, was considered to be a period of rebirth in western Europe after the Middle Ages. So you see, even dredging was re-born.) When you consider he also designed a machine gun, a tank, a diving suit, a plane, and, a few hundred years before the Wright Brothers - a helicopter - I guess it’s not so surprising after all.

Model of Leonardo da Vinci's dredging boat. Yes, the image is flipped (you can tell by his writing). But it was the best image I could find of his drawing. Photo credit: Alamy.es

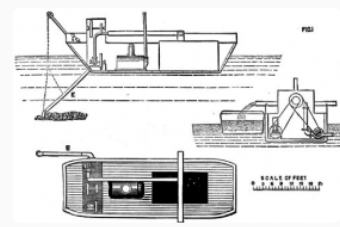

In 1857, the first suction dredger was constructed in the United States. Named the “General Moultrie,” it was put to work on the three rivers near Charleston in South Carolina. Unfortunately, it sank the very next year. But the method it pioneered has survived to this day. (Charleston is by far one of our favorite stops along the east coast. Every time we pass through, we see dredging operations in some part of this important channel and commercial harbor.)

The General Moultrie. Photo credit: Dredgepoint.org

In 1867, suction dredgers, designed by French engineer Henri-Émile Bazin, were used to begin construction of the Suez Canal. This type of dredger was a huge leap forward in the profession. (More about the Suez later.)

Drawing of the original Bazin concept for suction dredging. Photo credit: Dredgepoint

You have now advanced through time to the modern era of dredging. While suction dredgers are still being used today, there are now other, more sophisticated machines and methods employed. It seems there is no limit to the types of dredgers in use today. Here are the main types.

Modern Dredgers

Mechanical Dredgers

1) Bucket Dredgers

Bucket dredgers are the oldest type of mechanical dredgers that are anchored while in use, and can swivel or pivot in a semi-circle, dredging the surrounding area. They work using a massive rotating chain with external steel buckets on the external side that scoop up material and dump it onto a nearby barge for emptying elsewhere.

2) Bucket Ladder Dredgers

As the name suggests, bucket ladder dredgers are are modified bucket dredger, where the series of sediment-digging buckets is mounted on a wheel, instead of a chain. They are more efficient and can even rip up soft rock (or coral), but they are still not the most efficient method with relatively low production rates. These dredgers also generate a high amount of noise underwater, which can be harmful to marine life.

3) Grab Dredgers

Grab dredgers, also known as “clamshells,” are are held in position via anchors or on “spud-poles.” Spud poles are vertical (perpendicular) to the dredge barge and are lowered into the bottom to hold a barge in place. (We see plenty of these along the Intra-coastal Waterway. Grab dredgers gather sediment from the seabed with a clam grabbing motion and either move it aside or carry it away on barges. The cutting/gathering tool, of these these dredgers, is a grab that consists of two half-shells. The grab is mounted either on a dragline or a hydraulic excavator. Grab dredgers can be open grab, closed grab, or watertight grab. Grab dredgers are efficient at removing material from dock corners, dock basins, and adjacent to quay walls. Grab dredgers can be of different capacities, ranging between 1.0 m³ and 20 m. Their capacity largely depends upon the power of their crane.

The world’s record largest grab dredger is called the Gosho grab dredger, made in 2011 by Mitsubishi in Nagasaki, Japan. Its massive bucket is 9 meters (29 ft) tall, by 13 meters (42 ft) wide, by 9 meters (19 ft) long. In fact, Gosho’s bucket is so large, it could almost fit our Nordhavn 47 inside!

Gosho's maximum hoist load is... wait (weight) for it... 690 tons! That’s 1,520,000 lbs! That means it could lift the upcoming Nordhavn 148, at 495 tons or 1,100,000 lbs, with each bucket load!

Hydraulic Dredgers

1) Backhoe Dredgers

Also referred to as dipper dredgers, these are similar to normal excavators that are used for digging and construction on land. These are used for shallow water dredging, are hydraulically operated, and consist of a digging bucket which is capable of digging a wide range of materials. When the dredger's bucket/shell is filled, it is then emptied onto barges for hauling away. However, backhoe dredgers are not good for deep water dredging (i.e. a 50 ft deep shipping channel) because their depth is limited by the length of their hydraulic arm.

It was cool watching this backhoe dredger on Chesapeake Bay near Baltimore. And check it out. He's Cashman! Digging for cash.

2) Suction Dredgers

There are two types of suction dredgers. Basic suction dredgers and cutter suction dredgers.

The basic suction dredger is used to remove sand and silt and cannot be used on rock or coral. They use a suction pipe, which is shoved vertically inside the sand/silt that had deposited due to current. The material is sucked up with or without the aid of a water jet. We see several of these each time we run up or down the Intra-coastal. The length of their pipes can be incredible. We've watched some go by that were so long, they had to span them between three tugs. It was like watching a train of tanker cars!

Cutter suction dredgers are far more commonly used because they just make so much more sense. They work fine for sand and silt, but can also dredge clay, rock, coral, and other sorts of materials. These machines grind up whatever is on the bottom, and then suction it up with heavy duty, wear-resistant pumps. This type of dredger pivots on a steel rod that is driven into the bottom using thrusters.

Both of these suction dredgers will sometimes deposit their material in a stream of water, shooting up like a 45-degree fountain, away from the dredging site, sometimes forming a small island. Other times, the material is barged away.

Here's are two close up photos I took of the heads of Cutter Suction Dredgers. These are the most common type we see on the Intra-coastal.

3) Trailing Suction Hopper Dredgers

Trailing suction hopper dredgers are self-driven dredging vessels (meaning, no tug is needed), used mostly for harbor maintenance and pipe trenching. They consist of trailing drag arms and suction pipes, which fill their own holds/hoppers. Once the hopper is loaded, the material is hauled away, then released through gates on the vessel’s bottom

This dredger is most commonly used in challenging sea conditions, when dredged material must be transported greater distances, and for land reclamation.

4) Water Injection Dredgers

Water injection dredgers are self-driven. As their name suggests, they use jetted water to loosen and remove sediment. The water is so powerful, it fluidizes material until it is in suspension (which is a fancy way of saying “becomes very dirty”). This suspension is then carried away by water currents until, eventually, gravity lets the sediment precipitate out and sink once again, but in a desired area. This type of dredger is generally used to dredge mud or fine sand bottoms and where environmental sensitivity is more important.

Other Types of Dredgers

1) Jet-lift Dredgers and Air-Lift Dredgers

Jet-lift dredgers work on the principle of the Venturi effect. A high-speed stream of water is injected, pushing the adjacent water, along with the bed material, into a delivery pipe.

2) Augur Suction Dredgers

Augur Suction Dredgers work somewhat like mechanical cutter suction dredgers, except they are equipped with a rotating Archimedean Screw for cutting, which is placed perpendicular to the suction pipe. The augur rotates and removes material and delivers it to the centrally placed suction pipe. This dredging method is employed where the material is to be dredged in precise vertical and/or horizontal dimensions.

3) Reclamation Dredgers

Like the name suggests, this type of dredger is generally used for reclamation purposes. These are also referred to as “barge unloading dredgers.” We have seen these in operation, rebuilding eroded beaches along the Atlantic coast.

The most extreme use of this form of dredging is Palm Jumeirah, in Dubai, where 3.2 billion cubic feet of sand was pumped from the ocean to artificially create the sculpted shape of this upscale development.

4) Pneumatic Dredgers

Pneumatic Dredgers work on the same principle as a vacuum. They consist of a chamber with high vacuum pressure inside. The chamber is suspended with the help of a crane. Bed material is sucked into the inlet chamber through a vacuum until the chamber is full. The chamber is then lifted up by the crane and emptied away from the dredge site.

5) Amphibious Dredgers

Amphibious Dredgers are a great technical advancement, as they can work in both submerged and elevated conditions. They are equipped with either grabs, buckets, or a shovel. As the name suggests, these dredgers prove useful when material to be dredged is both land based and underwater.

Image source: Watermaster.fi

6) Plough or Bed Leveler Dredgers

Now these are different. Rather than remove material, they mostly just move it, or allow currents to move it, meaning they do not require disposal sites. Plough or bed leveler dredgers mostly sweep or rake across the bottom to level out irregularities in depth, caused by current or even previous dredging work.

Environmental Impact of Dredging

While the main purpose of dredging is to move sand, silt, coral, and rock to suit navigation needs, and while we, as boaters, greatly benefit from dredging operations, it is important to understand the environmental impacts that arise from this.

The main impacts can be classified as:

- Entrainment;

- Habitat degradation;

- Noise;

- Remobilization of contaminants (stirring up bad things on the bottom that had been sedimented over);

- Sedimentation; and

- Increase in suspended sediments.

Entrainment refers to the unintentional uptake of organisms by the suction field (or a field disturbed by another form of dredging). Hydraulic dredgers are the main culprits here, in part because they are so efficient.

Habitat degradation mainly affects seagrass beds and coral reefs. These are important ecological habitats for numerous species. The good news here is there is less damage through current dredging than in the past, as a result of increased knowledge on the subject.

Marine mammals rely on sound to detect prey, navigate, and communicate with one another. While the noise of a dredging operation might be a nuisance to people living nearby, it's nothing compared to the noise carried underwater. Note that sound travels way farther underwater than on land.

While the remobilization of contaminants such as hydrocarbons and heavy metals such as lead, mercury, arsenic, and chromium sounds terrible, studies have shown this not to be a widespread problem for marine life. It is, however, a local problem in certain formerly industrial areas. In highly contaminated areas remediation dredging with specialized equipment is used to clean up bottom contaminants with reduced spread to surrounding waters - a good thing.

Sedimentation is when high concentrations of sediments are suspended in water as a result of dredging. In other words, when water that is relatively clear or at least not murky becomes far murkier. This can cause damage to gills in fish as well as changes in predator/prey relationships. These plumes from dredging gradually dissipate, so the damage is temporary. In environmentally sensitive areas, dredging can be planned so not to coincide with spawning season.

To summarize, while cutting and digging are arguably the most environmentally invasive way to dredge, it can be said that water injection is the most environmentally friendly dredging method, since it is effectively just speeding-up nature's process of underwater erosion.

Famous Dredging Projects

Any post about dredging wouldn’t be complete without researching and sharing facts about some of the most fantastic dredging projects completed by mankind. Some of these have changed the world by changing the economics of the world and thereby the key powers.

The Suez Canal

The idea for the Suez Canal originated thousands of years ago. In fact, there's some evidence a series of canals had been built in the area as long ago as 1850 B.C. connecting the Red Sea and the Nile River, which then led to the Mediterranean.

Fast forward over 3,500 years to Napoleon Bonaparte. Napoleon considered building a canal directly from the Mediterranean to the Red Sea to extend the power and wealth of France. So he sent in a team of surveyors. Unfortunately, they made a grave mistake and reported the Red Sea was 30 feet higher than the Mediterranean, making the project seem unfeasible at the time.

Not long afterward, the idea was championed by Ferdinand de Lesseps, a French diplomat based in the area. He founded the Suez Canal Company, owned approximately 50/50 between the French government and citizens and the ruler of Egypt. Construction soon began, initially by hand and then aided by French machines. The 120 mile canal was completed in 1859, ten years later, when digging teams met at approximately the mid-point. Among 1.5 million workers, an estimated 120,000 died, mostly from epidemics. After completion, Egypt had to sell its shares to the British because it could not afford the debt. Soon after, Britain sent in 30,000 troops to essentially control Egypt. That uncomfortable situation lasted until 1956 when Gamal Nasser, the Egyptian leader, nationalized the Canal. The French and English tried to take it back without success, in part because of political opposition from the U.S.

Today,19,000 ships pass through the Suez each year, with tolls that can reach up to $1,000,000 per vessel! In total, over $3.3 trillion in trade pass through the Suez annually, representing 12% of global trade. That’s over $9 billion daily, nearly $400 million per hour, around $6.3 million per minute, and roughly $100,000 per second. The Canal has become an essential component of East-West trade. At current shipping speeds, the Canal saves around 5,500 miles distance and around 3-weeks at sea by bypassing the horn of Africa, along with its sketchy weather. I think you could say this was a dredging operation of extraordinary benefit worldwide.

In recent history (as in 2021), the Suez became famous all over again, and the whole world became aware of its importance to commerce. On March 23, 2021 a 1,312 foot long, 193 foot wide, 52 foot draft ship called the Ever Given lost control in a narrow part of the canal and became wedged diagonally, blocking all traffic and causing global supply chain disruptions. My dad and I felt sorry for the captain. In time, every captain will make one or more mistakes. But its really bad when your mistake is worldwide news for weeks and is visible from space. Eventually the ship was freed using excavators, tugs, tides and... you guessed it... a giant cutter suction dredger moving up to 70,000 cubic feet of sand per hour. Over 300 ships were held back by the Ever Given. The cost of the accident was staggering and the lawsuits will make it far costlier.

The Panama Canal

“I believe that we are but children picking up pebbles on a boundless ocean”.

-- John Frank Stevens, American, Chief engineer of the Panama Canal.

The Panama Canal, constructed between 1881 and 1914, is a giant shortcut that eliminates 13,000 miles from the voyage between the Atlantic and Pacific oceans, while simultaneously moving marine traffic away from the notoriously dangerous Cape Horn (at the bottom of South America - some of the worst weather in the world). However, like many ambitious engineering feats, the project came at great cost. Altogether, the construction of this 40 to 50 mile long canal cost $375 million at the time* - over $10 billion today - along with the loss of 25,000 lives. Most of these workers lost their lives through landslides and disease (primarily malaria and yellow fever, which are both spread by mosquitos, but not the same type of mosquito).

It all began in 1881, when the French diplomat Ferdinand De Lesseps tried to cut through the mountain range that runs through Panama and down to sea level. Yes, this was the same De Lesseps who was responsible for the construction of the Suez Canal. And, wait, you say. Down to sea level? Going between the Atlantic and the Pacific? Yes indeed. It might interest you to know that sea level of the Pacific is about 8 inches higher than the Atlantic. But the bigger issue De Lesseps faced was the terrain. There are mountains between those oceans, the tallest of which is 11,400 feet. It seems reasonable to assume Monsieur De Lesseps, following his success at Suez, was overly confident of success at Panama.

*Actually, the cost of the Canal was double this amount. $375 million is what the Canal cost the United States. But France lost nearly that amount with their failed initial endeavor. (More about that below.)

Fortunately the spot where the Panama Canal was proposed, called the Isthmus of Panama, did not have nearly that much elevation.

But the proposed land still reached a height of around 600 feet. This meant cutting down 600 feet of land, plus another 50 feet of depth for the ships.

After 9 years and many thousands of deaths the French abandoned the project. The financial loss to the French government and hundreds of thousands of individual French and other European shareholders approached or may have exceeded $300,000,000.

The U.S., meanwhile, had been thinking of building its own canal through Nicaragua. But when the French abandoned Panama, the U.S. determined to succeed where France had failed. Panama was in favor of a canal — regardless of who built it — because the country stood to benefit greatly from the wealth transiting through it. But Panama, at the time, was still part of Colombia, and the U.S. and Colombia could not come to terms over the land. The newly elected President of the U.S. at the time, Teddy Roosevelt, decided to support the Panamanian people’s interest in ceding from Columbia to form an independent country. With limited military support from the United States, and not a dollar’s payment to Columbia, Panama succeeded in becoming its own country, with much gratitude to the U.S. It was a brilliant move by Roosevelt!

The U.S. still needed a Canal plan that did not involve digging through and dredging millions of tons of rock and dirt for 40 to 50 miles. Luckily, the right man, and plan, came along.

The U.S. design called for 5 locks* to lift the ships up and over the terrain.

* A lock is a system that lifts ships up and down over land, bridging the gap between different water levels as well as over higher land, thereby reducing the need to excavate and dredge.

Vessels are raised inside a lock by pumping in water. They are lowered by draining out that same water.

Using locks for Panama was a great idea, especially considering the alternative. Possibly it was the only feasible way.

But the U.S. plan was even more clever. WAY more clever. To make the Panama Canal far easier to build, engineers constructed a dam, to raise inland water levels and create an inland lake. Ships travel 21 miles inside Panama across this lake. The dam was the largest ever constructed in its time, at 105 feet tall and 2700 feet wide, containing 600 million cubic meters of material. Called the Gatun Dam, it is still in use today.

In total, the Panama Canal raises ships 85 feet, and then lowers them back down. The U.S. construction of the locks, dam, and canal cost another 5,000 lives. But in 1913, dynamite explosions finally severed North and South America, connecting the world’s greatest oceans. This enterprise played a huge role in the rise of the U.S. as a global superpower. It changed the world.

Before moving on from the Panama Canal, it's worth taking a few minutes to explain how the U.S. managed to significantly reduce the death toll of its project. Back in 1897, a British citizen living in India proved that mosquitos transmit disease. But it took some time for that knowledge to reach the U.S. and be applied to the Panama project. The man who did it was Colonel William Crawford Gorgas, appointed in 1904 to head hospitals and sanitation. He systematized healthcare on the job site with military discipline and with measures including clearing land and building quarantine facilities. His greatest contribution, however, was working with chief engineer John Frank Stevens to drain and treat (with oil and larvicide) massive amounts of nearby standing water where mosquitos lived, and to design and install a true freshwater system, eliminating the need to collect (stagnant, mosquito-breeding) rainwater for drinking. Fumigation with sulfur and pyrethrum was also extensively used. So, he literally fumigated the entire jungle! Lastly, the U.S. government provided $20,000,000 for healthcare and burial services, along with extensive supplies of quinine to help inoculate workers.

So how successful was all this effort and cost? Staggeringly successful. Within a year of the combined efforts of these two leaders, every building in Panama had been fumigated. In 1906 there was only one (1) case of yellow fever and, after that, through 1913, there was not a single other case. While malaria cases persisted, proper quarantine and healthcare dramatically reduced the death rate.

Without question, construction of the Panama Canal brought the world new knowledge of disease management. Quite possibly - perhaps likely - the number of lives lost pales in comparison to those saved with this advance in medicine.

The Intra-coastal Waterway: (ICW)

Ok. So after Suez and Panama, America's Intra-coastal Waterway (ICW) might seem pretty small in importance. And I guess it is, relatively speaking. But the ICW is dear to our hearts as live-aboards.

The ICW is a 3,000 mile-long waterway that starts in Boston, Massachusetts, travels down the entire Atlantic coast to Key West (though not quite that far for a deep draft Nordhavn - we need to go outside to do the Keys). It also continues up the west coast of Florida, through Alabama, Mississippi, Louisiana, and finally ending in Brownsville at the boarder between Texas and Mexico.

A waterway inside the East Coast was first conceived by Congress in 1808 at an initial estimated cost of $3 million. (Of course, many years later, after the project and improvements were completed, the total cost was much higher.) The ICW was seen as a way to move goods and people up and down the coast in times of peace or war. The plan was to begin in Boston but end in Georgia, because Florida was not yet a part of the colonies. In total, the construction took over 150 years because small bits and pieces were added over time. Once the entire waterway was built, it was lightly used for a little while, then used even less during the Civil War and after because freight was increasingly being moved by train. People realized that there needed to be a better way to move bulk goods up and down the East Coast. During World War II, the ICW was used considerably for strategic reasons: namely, it allowed goods to travel up and down the coast unthreatened by German U-Boats.

The ICW is the number one way my dad and I have travelled in our Nordhavn. Though our boat can handle pretty rough seas, we handle them not so well. And until my mom joined us part-time last year and full-time this fall, he's almost always been the only adult aboard. We’d rather not take chances with seasickness. Without the Intra-coastal, it would be much harder on us to travel up and down the East Coast. We’d have to do it a lot more around weather, and make bigger distance jumps in those weather windows. We’d also miss out on some amazing beauty and wildlife. (The Waccamaw River in South Carolina and the marshlands of Georgia are some of the most peaceful and beautiful.)

The Intra-coastal is maintained by the U.S. Army Corps of Engineers to a minimum of 200 feet wide (although there's a stretch in the Grand Strand that sure feels narrower than that!). It is legally supposed to be no less than 12 feet deep (ha!) at mean low water (MLW), the average of all tidal heights recorded over time, but funding has made a minimum of 9 feet or even less the reality. Given our Nordhavn drafts around 6 feet (we round up from 5.5 feet), we are good to run the entire Intra-coastal as far south as Miami, though we do have to watch the tides and inlets carefully. The inlets pose the most frequent issue for us as they tend to silt up -- sometimes pretty quickly. We are always grateful when we see the Army Corps surveying and the Corps and third party companies dredging those troublesome areas.

Erie Canal

So if the ICW seems minor in impact compared to Suez and Panama, I'm now at an even smaller (though like the ICW, still important) canal: the Erie Canal.

As we wrote in an earlier blog post, our Nordhavn came with a rare, optional hinged fiberglass stack. When lowered, our air draft (height) is reduced from 28 ft to 21 ft, allowing us to go under fixed and non-fixed bridges we otherwise could not. By mere inches, this enabled us to do a round trip on the Erie/Oswego Canals. It was a beautiful and peaceful experience and saved us over 2,600 miles round trip by avoiding the St. Lawrence Seaway and its mouth at the Atlantic (along with the iffy weather there we’ve often seen on the Windy app. It also helped us master the new skill of navigating a lot of locks.

We looked into the Erie’s history and here’s what we learned. The Erie Canal is the second longest canal in the world at 363 miles long. It starts at the Hudson River, 10 miles north of Albany, New York and ends 10 miles north of Buffalo.

The first proposal for the canal was in the 1780s. It was then re-proposed in 1807. A survey was authorized and the funds were raised in 1808. Construction began on July 4 (yes!), 1817. Only 8 years later, and this included the construction of 34 locks which raised or lowered vessels 563 feet between Lake Erie and the Hudson River. It was completed in 1825 and opened October 26 of the same year. The cost was $7 million in 1825 dollars (about $200 million in today’s dollars). This was a big undertaking for a country that was only 40 years old.

Here is a drawing of all of the locks showing how much each one lifts or lowers, and the distance between them. You can see how sharply and rapid-fire the lift begins Eastward from the Hudson River (on the right). It was trial by fire for us as we were total newbies to locking.

The Erie Canal cut the cost of transporting freight to central states by as much as 95%. Equally impressive is that the cost of construction was recovered in just 10 years. The Canal was enlarged between 1834 and 1862. But, then the railroads came. While the cost to transport goods on the Erie was inexpensive, it was also slow. Railroads were more expensive, but much faster. And, well, time is money. As a result, the Erie evolved into what it is today - a route for mostly pleasure craft like ours with a handful of barges thrown in.

For a video on the Erie Canal's construction, over 200 years ago, click here.

While the Erie was originally hand dug, today it is maintained by modern hydraulic dredging, offloading material directly to onshore sites.

Our experience on the Erie Canal was some of the most beautiful boating we've done. It was so peaceful. In fact, many times, we had it to ourselves.

I learned how to lock on the Erie. In fact, I went through about 50 of them round-trip. Whenever we approach a lock now, I look forward to it.

While we waited for this lock to open, two separate freight trains crossed this fixed bridge. My Dad was still a relatively inexperienced Captain. Try to imagine how anxious he was waiting to slip under it, first given how low it was, and second, wondering if another freight train would come along at the same time.

...as were the flood safety gates. Thank goodness one of our crew thought to tie the radar antenna horizontally when we lowered our mast! Every inch mattered.

Here's a time lapse video from a fellow cruiser of what it's like to go through some of the Erie's locks.

And lastly, I know I linked to this song in an earlier post, but it's just impossible to even say "Erie Canal" without thinking of the folk song. I chose this version this time because it has interesting, animated historic photos to go with the music. Enjoy.

Welland Canal

The Welland Canal is considered one of the shipping wonders of the world. It's a very important shipping canal in Ontario, Canada that connects Lake Erie to Lake Ontario. It is an essential part of the St. Lawrence Seaway. While those two Great Lakes are naturally connected, boating over Niagara Falls is probably not a good idea, even in a Nordhavn. And boating up the Falls would be kind of difficult.

Construction of the first Welland began on November 30th,1824. It opened exactly 5 years later, to the day, in 1829. The original contained 40 locks. It was not dredged very wide or deep (8 feet was the minimum depth). And that's a big part of why there have been 4 iterations of the Welland. Upon constructing each lock, it was deemed that a larger one would be needed. The original was so popular and under-built for its demand that there were frequent collisions between ships, while others awaiting passage would be iced-in when winter arrived.

Part of what's left of the first Welland Canal. Note the stone blocks and how small each lock is. The smallest was only 110 ft long and 20 ft wide. Photo source: Google images

Part of what's left of the first Welland Canal. Note the stone blocks and how small each lock is. The smallest was only 110 ft long and 20 ft wide. Photo source: Google imagesThe current Welland Canal, built between 1913 and 1932, is the 4th canal connecting these waterways; three smaller predecessors also bore the same name. It is 27 miles long and consists of 8 massive locks raising and lowering vessels 326 feet between Lake Ontario and Lake Erie. 7 of the 8 locks each lift vessels 46.5 feet. The massive 8th lock is a control lock for the entire Canal and lifts around 12 feet. The Welland was built at a cost of $132,000,000 in 1932 -- 3 times the initial estimate, though in today's dollars (under $1 billion), still a value. The Canal currently carries 3,000 ships annually with 40,000,000 tons of cargo.

All 4 Welland Canals were very difficult to construct because of the terrain. But the 4th one -- far wider and deeper -- was the most daunting of all. Not only did engineers and builders have to contend with incredibly rocky terrain, but the project was plagued with funding shortages, labor shortages, unexpected engineering problems, electricity shortages and... the outbreak of World War I.

Here's what's amazing about this photo. As massive as the excavation is, you are seeing only 1/2 of Lock 5. The lowering side. You can just barely see the sister basin to the right side of this image. Photo credit: stcatharinesmuseumblog.com

Even today, as large as it is (minimum depth is 28 feet), the Welland is too small for many ocean going ships. (By comparison, the Suez can handle vessels with a draft of 66 feet.) As big as its locks are, the maximum length a ship can be is 740 feet. (The Suez can handle vessels nearly twice that length.) So tight is the squeeze for certain ships that fires will break out from the friction between their hull sides and timbers lining the lock walls.

The huge impact of the Welland Canal is hard to measure. It’s safe to say the cities of Toronto, Cleveland, Detroit, Milwaukee, and Chicago, as well as other heavily industrialized areas of the Great Lakes and Ontario benefitted enormously from the interconnectivity the Welland enabled.

My Dad and I took our Nordhavn through the Welland twice in 2019. Here are some of the photos we took.

I will end this bit about the Welland Canal with a really fascinating fact: it is completely energy independent. Meaning, all its power needs are met through its own falling water passing through three 5,000 hp turbines!

And why not a little drama from the Welland? Here's a video of a well known accident that happened back in 2001. Though the pilothouse was destroyed, amazingly, no one was killed.

Lastly, here's a more recent accident. Even with today's wider Canal, ships still pass in close quarters. Though the accident is still under investigation, I'll bet there was a steering failure.

__________

In wrapping up this section about some of the great, dredged canals, it's worth comparing a few statistics of the ones we've covered:

- Suez: distance 120 miles, 0 locks, elevation change <2 ft.

- Panama: distance 50 miles, 3 locks, elevation change 85 feet.

- Erie: distance 363 miles, 36 locks, elevation change 565 feet.

- Welland: distance 27 miles, 8 locks, elevation change 327 feet.

It's interesting to see how short and steep the elevation change is for the Welland vs the other canals.

__________

We hope you've enjoyed our post about dredging history, machines, and some of the amazing waterways dredging has created.

P.S. We feel badly it's taken us a long time to finish this post. As I (Salter) have begun focusing on writing more for my schoolwork, I will try to make my next post much sooner.

P.P.S. During the past month, we've run soft aground twice in the middle of the ICW channel near Sullivan's Island, SC. And yet we also managed to pass through that same spot several times, including weeks ago at absolute low tide. It's weird how quickly shoaling can happen, and how the bottom can simply move within days. After three and a half years of boating, and since there was no damage to our boat, we've learned to just roll with it. Check out my dad's notes on our chart. :)

Certainly learned a few things. Thanks. Maybe you can follow up the the TennTom Waterway. I believe it was finished in 1980 and was a larger project than the Panama Canal. And don’t forget the Richleau or the Trent Severn in Canada. Those are very cool. Even the Soo Locks. The list is long.

ReplyDeleteThank you. I had heard of some of those but not the TennTom. I wish our boat could have done the Trent Severn but we draw a bit too much. Interestingly an article came out a couple days ago about another proposed canal near Panama. I never knew that had been considered. Here is a link. Thank you for reading my blog. https://www.bbc.com/future/article/20230825-the-rival-to-the-panama-canal-that-was-never-built

DeleteGreat research! Kudos!!

ReplyDeleteThank you!

Delete